Laboratory freeze dryers operate on the principle of vacuum drying, designed to remove water from materials while preserving their integrity. By freezing water-containing substances and then sublimating the frozen water directly into a gaseous state, these devices offer efficient water removal and material preservation. This article delves into the composition, usage, and benefits of laboratory freeze dryers, essential tools across various scientific and technical domains.

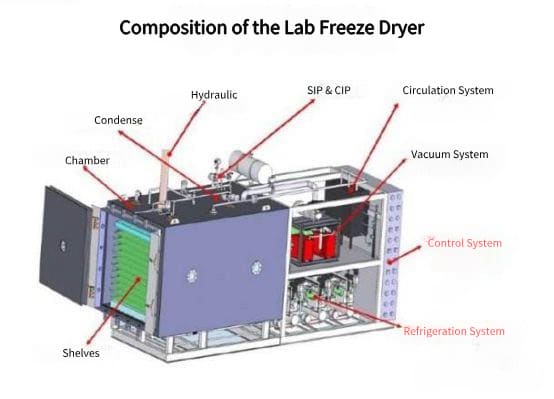

Composition of Laboratory Freeze Dryers

Laboratory freeze dryers consist of a compact arrangement of components that facilitate effective freeze drying of small sample quantities. Comprising a shell, refrigeration unit, vacuum pump, cold trap, and an electric control system, these devices are integral to laboratory research. Key components include:

Refrigeration System: Housed within the casing, the refrigeration unit encompasses a compressor, heat exchanger, expansion valve, and evaporator. This unit aids in cooling and freezing the materials.

Vacuum System: Connected via a vacuum pipeline to the cold trap, the vacuum pump ensures the creation of a controlled low-pressure environment for sublimation.

Cold Trap: Positioned atop the casing, the cold trap collects the sublimated water vapor, preventing it from contaminating the vacuum pump and aiding in maintaining a vacuum.

Material Placement: A designated area above the cold trap and shell accommodates the placement of materials, allowing for efficient sublimation.

Electric Control System: Responsible for regulating various processes, the control system ensures stable performance and user-friendly operation.

Using a Laboratory Freeze Dryer – Step by Step

Operating a laboratory freeze dryer requires precision and attention to detail. Follow these steps to ensure successful freeze drying:

Retrieve the Pre-freezing Rack: Remove the pre-freezing rack from the cold trap.

Load Materials: Place the pre-frozen materials onto the drying rack.

Position Drying Rack: Position the drying rack on the cold trap.

Secure Plexiglass Cover: Confirm the integrity of the sealing ring and absence of debris, then place the plexiglass cover securely.

Seal the Drain Valve: Rotate the drain valve clockwise to seal it.

Initiate Vacuum Process: Start the vacuum pump and monitor the decreasing vacuum gauge reading. A value below 20 pa during drying is normal.

Hang Flasks: Hang the flasks on the manifold valve. Open the valve to initiate drying, and subsequently close it once contents are dried.

Conclude Drying: Open the water intake valve and turn off the vacuum pump. If capping is needed, follow the correct procedure to ensure air-tight sealing.

Shutdown Procedure: Turn off the power supply, close the water inlet and valve, defrost the equipment, and clean it.

Maintain Equipment: When the vacuum pump is inactive, cover the exhaust hole to prevent dust ingress.

Applications and Benefits

Laboratory freeze dryers find applications in diverse fields such as biopharmaceuticals, chemistry, and food science. Their advantages include:

Faster Drying: Significantly shorter drying times compared to traditional vacuum drying and ovens.

Energy Efficiency: Consumes 2-3 times less energy than conventional methods.

Wide Temperature Range: Can effectively dry materials within the range of 0°C to 120°C, with fast drying possible at low temperatures.

Oxygen-free Vacuum: Ensures high-quality drying comparable to freeze-dried materials.

Solvent Recycling: Suitable for materials containing organic solvents, aiding cost reduction and environmental friendliness.

To learn more, consult laboratory freeze dryer manufacturers for comprehensive information and tailored advice on selecting the right device. These tools play a crucial role in advancing scientific research and technological innovation across various domains.