EPC, which is the abbreviation of edge position control. The automatic EPC photoelectric web guiding system is composed of a correction control board, correction controller, controller, actuator, etc. The edge or line part is tested by the photoelectric switch to pick up the deviation data signal and then wirelessly transmit the data to the photoelectric control board for logical operation, and send the manipulation data signal to the mechanical electric actuator. The electric actuator also known as electric drivers, drives the adjustment of the deviation during the operation of the coil material to ensure uniform linear motion. The EPC controller can be used for the waterproof coiled material guiding system. It provides edge alignment to avoid the deviation of the waterproof coiled material in the whole process of production and processing and ensure the accurate and stable performance of the waterproof coiled material in the entire production process with the neat division of the rewinding machine.

The control board can select the method of tracking the edge or line according to the different raw materials and chose the electric eye test to consider the requirements of various raw materials.

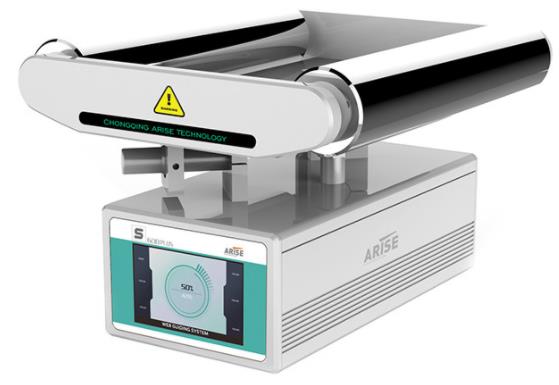

Advanced EPC Photoelectric Machine From Arise

Arise is one of the leading web guiding manufacturers in China, which focuses on the research, development and production of position sensors, web guiding and tension systems with photoelectric, CCD, color sensitivity and ultrasonic technology, can provide advanced EPC automatic photoelectric machine. The EPC photoelectric machine is an active control system for manipulating and correcting the direction deviation of the coil raw material during the whole process of high-speed transmission. It has the functions of active testing, active tracking, and active correction. It can be used for paper, non-woven fabric, plastic film, self-adhesive label tape, aluminum platinum, hot-rolled strip steel, etc. The edge or marking line should be tracked and guided by the control border to ensure the neatness division of the rewinding machine. The photoelectric correction manipulator adopts a universal photoelectric controller for edge alignment and line alignment, supplemented by imported drive machinery and a high-precision controller to control and keep the edges or the lines in a specific direction. The operation of the EPC machine is simple and the equipment has the features of high-precision, reliable, and wide application fields.