With the development of the aerospace industry, the demand for aerospace fasteners has increased rapidly. As aerospace fasteners are applied under an environment of high temperature, high pressure, and high intensity, their quality requirements are also particularly high. Here, we introduce some useful knowledge about aerospace fasteners.

The need for aircraft fasteners has increased dramatically as the aerospace sector has grown. Because aerospace fasteners are used in high-temperature, high-pressure, and high-intensity environments, their quality standards are exceptionally stringent. In this section, we will discuss some useful information concerning aircraft fasteners. A fastener is a type of mechanical device that connects two or more parts together. The scope of application is extremely broad. Aerospace fastener is a fastener that is specifically designed for use in the aerospace sector. It uses materials with unique qualities or applications.

Aerospace fasteners are commonly found in aircraft, satellites, and rockets. It is a standard high-end fastener. It is also a vital basic component of aerospace aircraft. The performance criteria are substantially higher than for other types of fasteners. There are several typesof aerospace fasteners, each with its own set of requirements and types to fulfill the unique needs of various materials and constructions.

What are the different types of aerospace fasteners?

1. Aerospace fasteners are divided as detachable and permanent fasteners based on their ability to be removed. Bolts, screws, and nuts are among the detachable fasteners. Permanent fasteners include high-locking nuts, rivets, and other similar items.

2. Aerospace fastener types include bolts, screws, nuts, single-sided fasteners, special fasteners, and so on.

3. Carbon structure steel fasteners, alloy steel fasteners, stainless steel fasteners, high-temperature alloy fasteners, aluminum alloy fasteners, titanium alloy fasteners, non-metal fasteners, and so on are the materials used in aircraft fasteners.

4. It can be split into single-sided fasteners and double-sided fasteners based on the variations in the requirements of the aerospace assembly operation.

Commonly used important aerospace fastener

Rivet fasteners

The most essential selection parameters for rivet fasteners used in aircraft are quality assurance and lightweight. It is one of the most common airplane fasteners. Aluminum alloy, stainless steel, heat-resistant alloy, titanium alloy, and other materials are used. The majority of rivets are made of composite materials such as aluminum alloy and titanium alloy. With the continual increase of rivet material intensity, support rivets used in corresponding vital sections, such as dual metal rivets and high shear rivets, have been created, and their strength can reach the intensity of titanium alloy high lock bolts.

Bolt fasteners

The bolt fastener, which includes regular bolts, high lock bolts, and tapered bolts, is the most commonly used fastening for bearing the bigger sections of the aircraft. A high lock bolt is a single-sided thread fastener that is commonly used in the aerospace sector. Weight loss is an essential signal in airplane design. High-ratio intensity materials can be used to substitute large-sized fasteners with lesser intensity. Furthermore, anti-fatigue, corrosion resistance, rigidity, brittleness, compatibility, heat resistance, and other features must be taken into account.

Nut fasteners

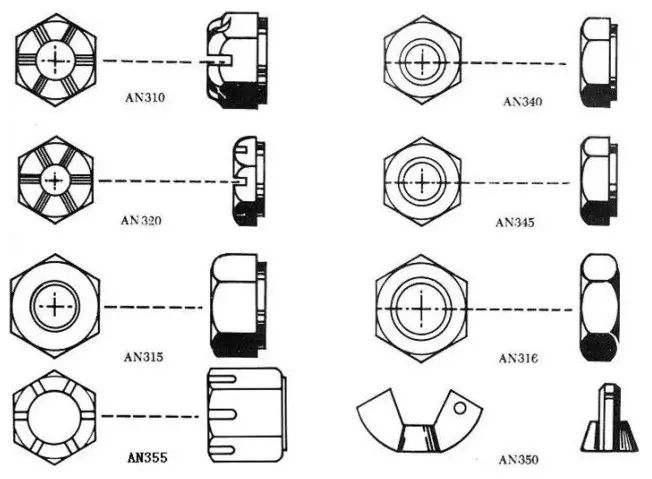

Nut fasteners are used in conjunction with bolts. They come in a range of structural forms to satisfy the needs of various aerospace applications, such as hex nuts, bihexagon nuts, bracket nuts, barrel nuts, and high lock nuts, the majority of which feature a self-lock construction. The hexagonal nut has been extensively used on the airplane. Bihexagon nuts are commonly seen on engine and high-strength bolts.

Single-sided fastener

In the open areas of the airplane, there are two types of fastening pieces. The bracket nut/bolt and rapid unloading fastener used in removable elements such as the airplane hatch is one example. The other is a single-sided nail, which is utilized in the permanent connection section. The screw thread nail is specifically created for the composite material structure, which can increase sealing and anti-fatigue performance.

Special fasteners

Ring grooved nails are a form of double-sided permanent fastener that is inserted with single-sided riveting. They are frequently utilized in Boeing and Airbus aircraft. The fast unloading fastener is mostly used to connect the cover to the hatch. It can perform fast loading and unloading duties and has a range of structural configurations. It has stringent reliability requirements. Composite fasteners, such as rivets, bolts, screws, and nuts, are formed of composite materials. It is a suitable aerospace fastener used to tackle problems in the aircraft such as weight, strength, corrosion, lightning strike, and other challenges.